Engineered for Endurance,

Designed by Fluiremax

Fluiremax Centrifugal Pumps deliver reliable, high-efficiency performance for a wide range of industrial applications. Engineered with precision and built for durability, our pumps ensure consistent fluid movement with minimal maintenance. Ideal for handling water, chemicals, and more, Fluiremax is your trusted partner for powerful, cost-effective flow solutions.

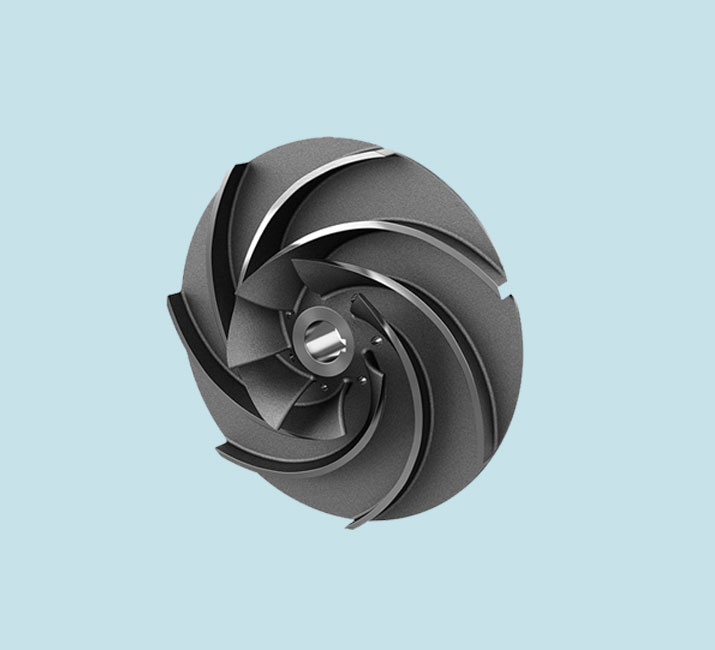

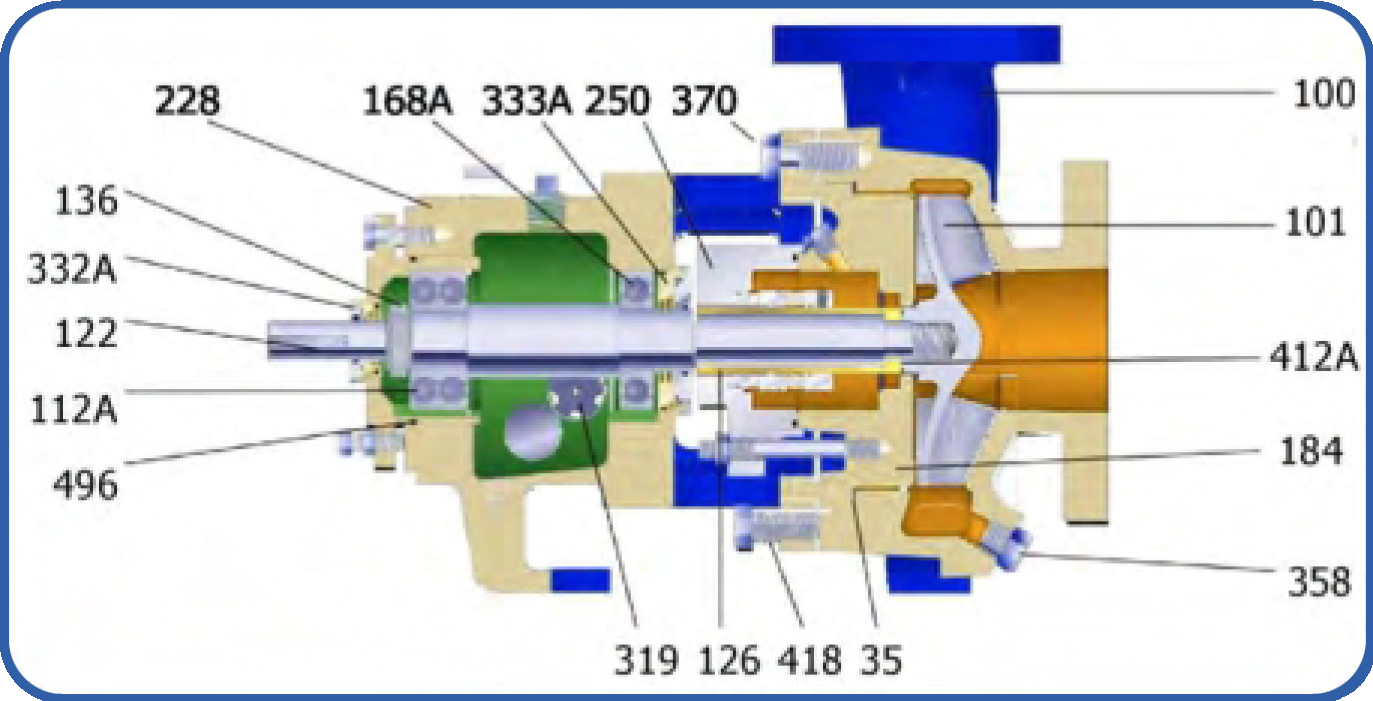

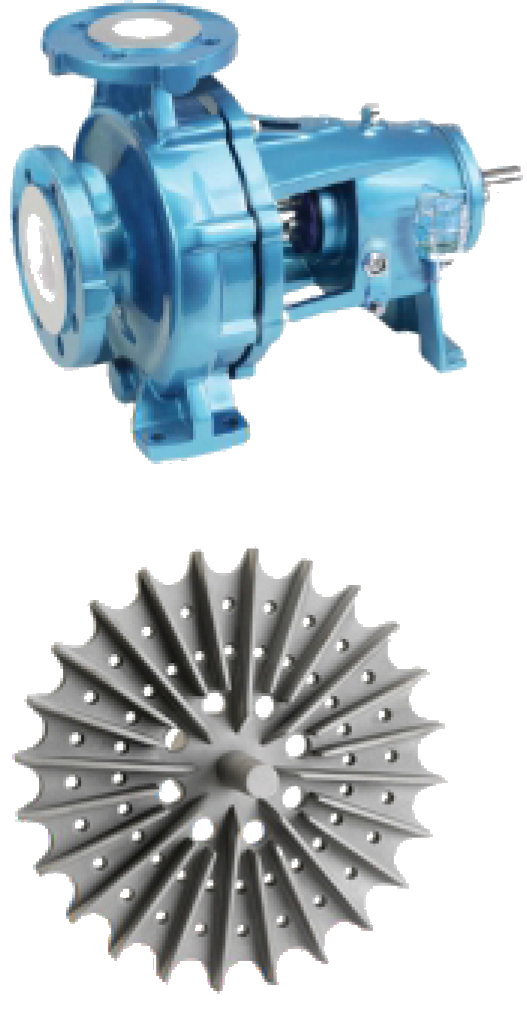

Semi Open Impeller

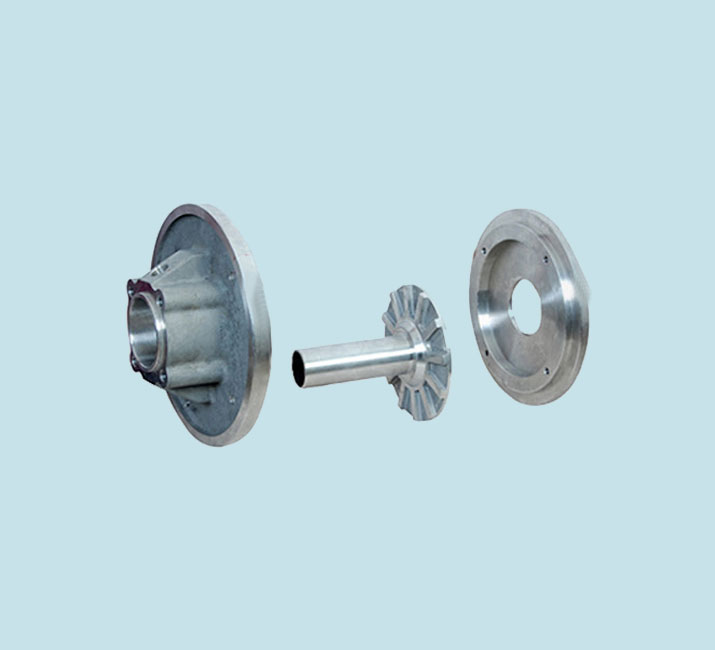

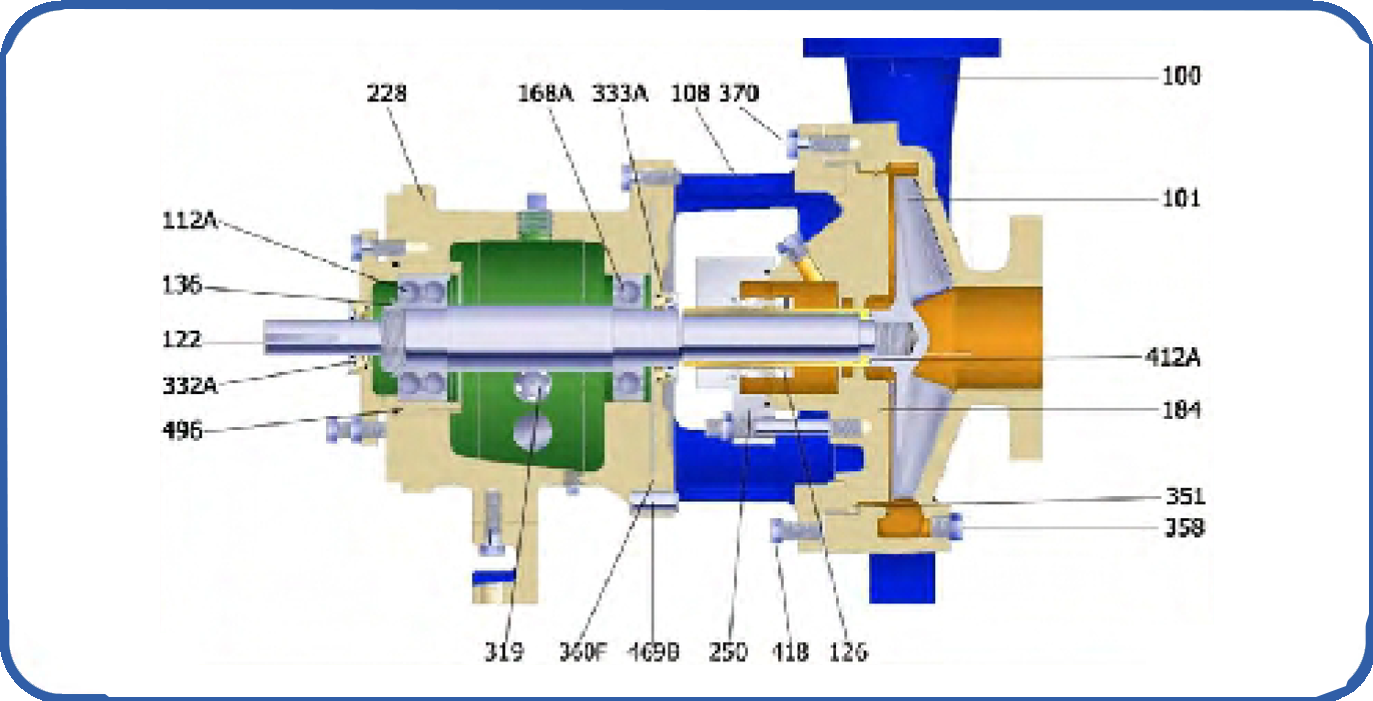

Stuffing Box Options

Standard Bore:

Designed for packing. Also accomodates Mechanical Seals.

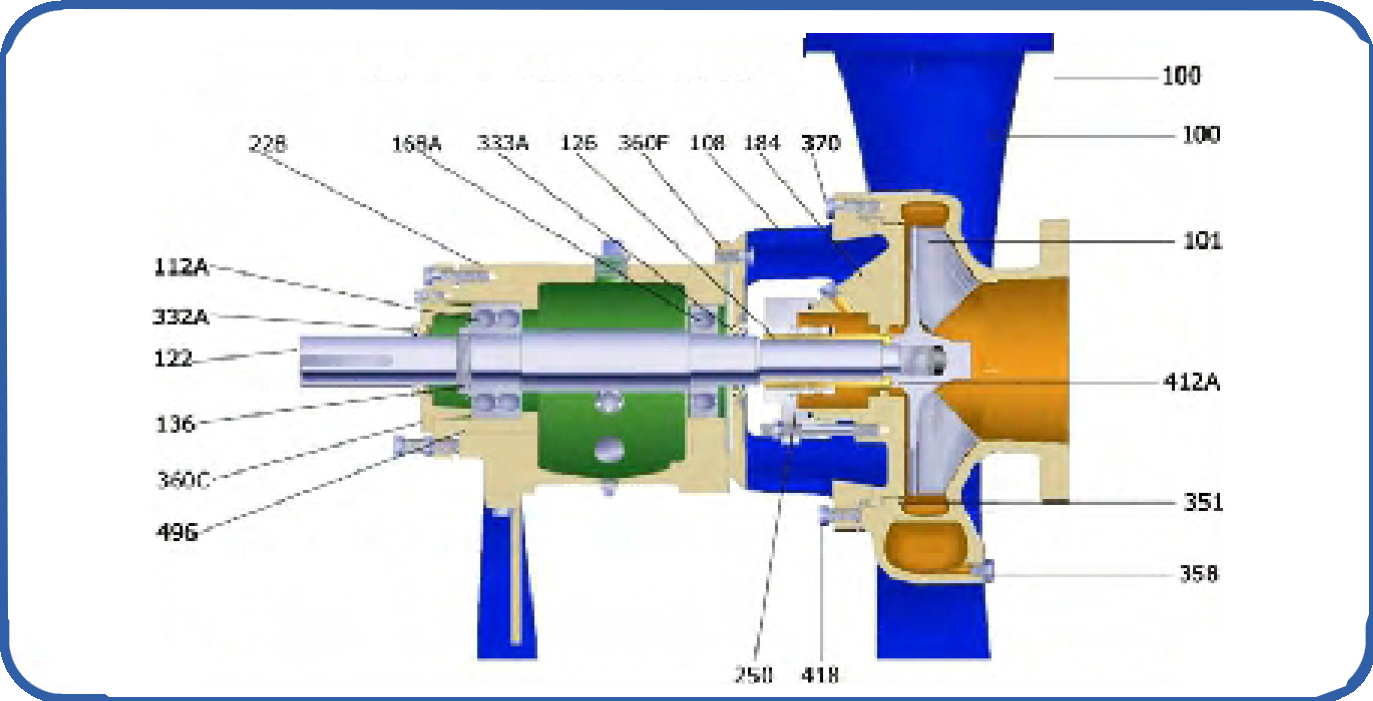

Big Bore:

Enlarged chamber for increased seal life through improved lubrication & cooling.

Taper Bore (Conical Stuffing Box):

Lower Seal face temperatures, self-venting & draining. Solids & Vapours circulated away from seal faces.

Dynamic Sealing Arrangement

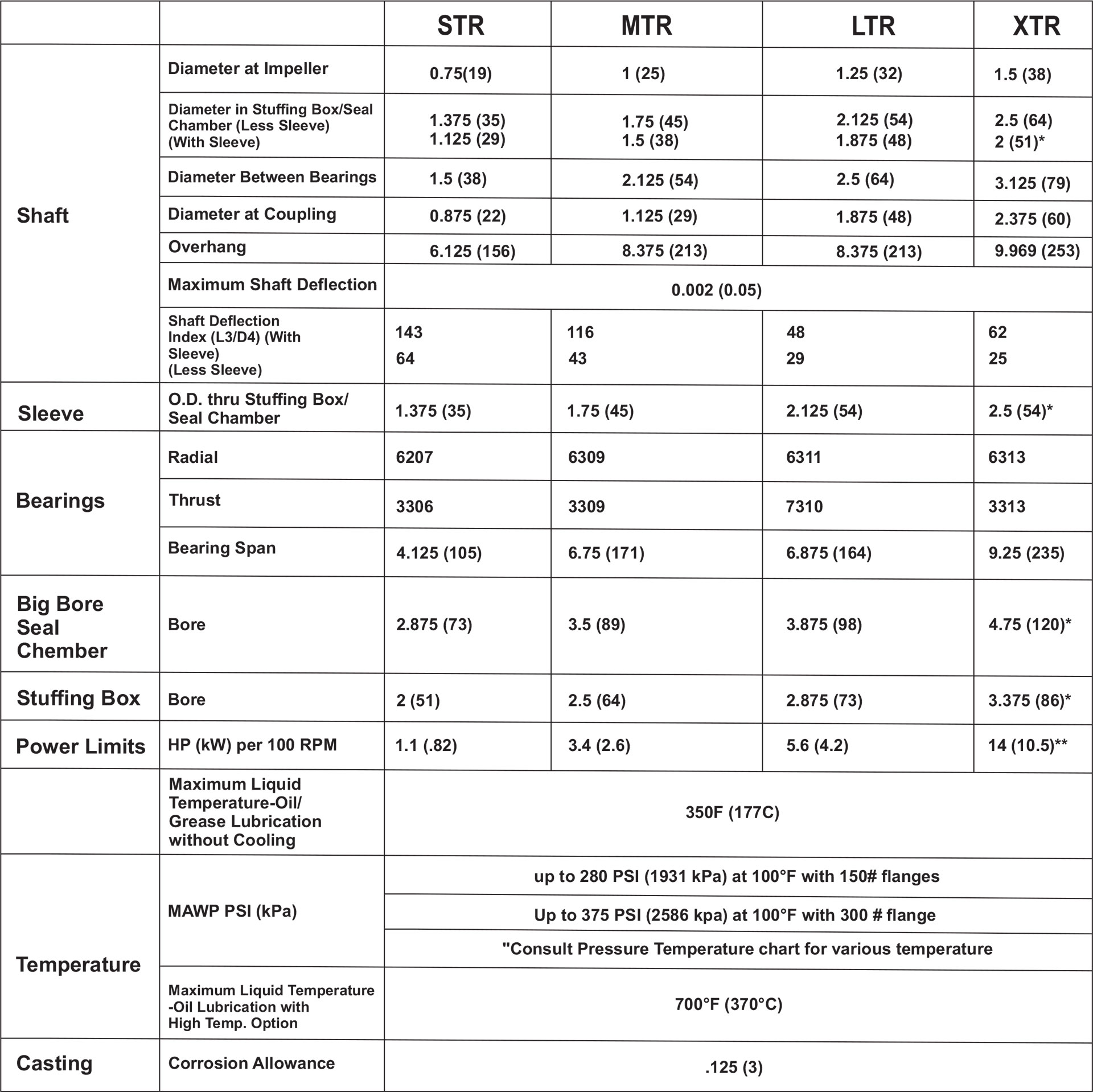

Specifications

| Water Based Liquids With Flush | Entrianed Air Or Vapour | Solids 0-10% No Flush | Solids Greater Than 10% With Flush | Slurries 0-5% | High Boiling Point Liquids No Flush | Self-Venting & Draining | Seal Face Heat Removal | |

|---|---|---|---|---|---|---|---|---|

| SB | A | C | C | B | C | C | C | C |

| BB | A | B | C | A | C | C | B | C |

| TB | A | A | A | C | A | A | A | A |

| A-Ideally Suited, B-Acceptable, C-Not Recommented | ||||||||

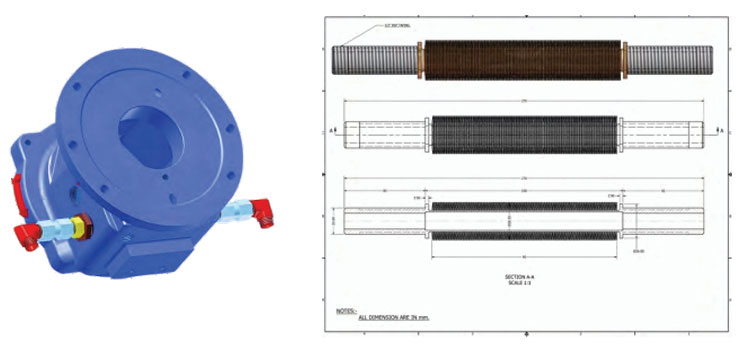

Jackets For Casing & St Box For (High Temperature & Crystallising Liquids)

Finned Tube Cooler Assembly For High Temperature Applications

Additional Features

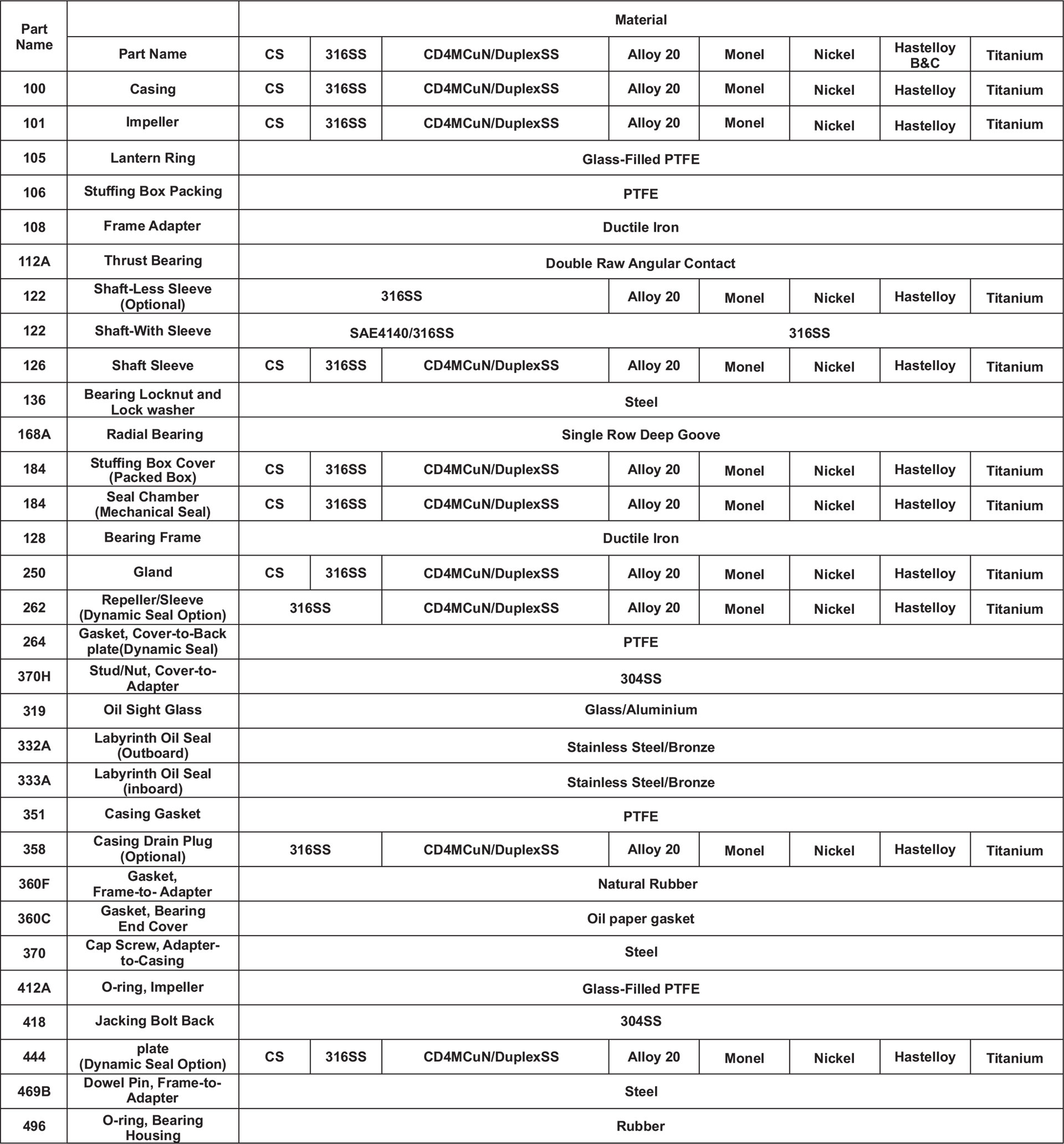

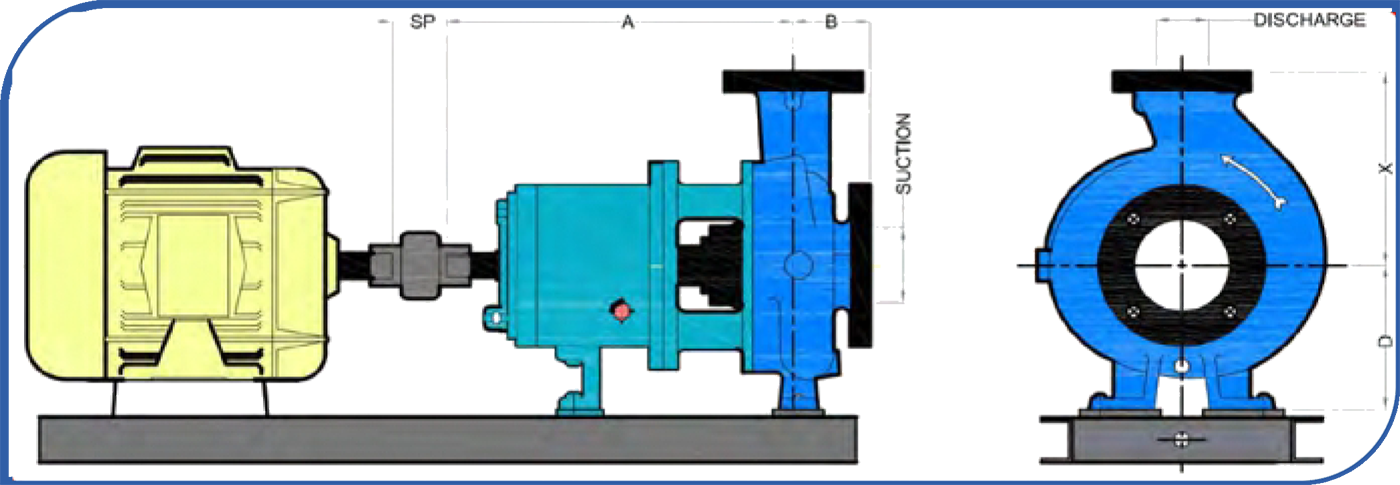

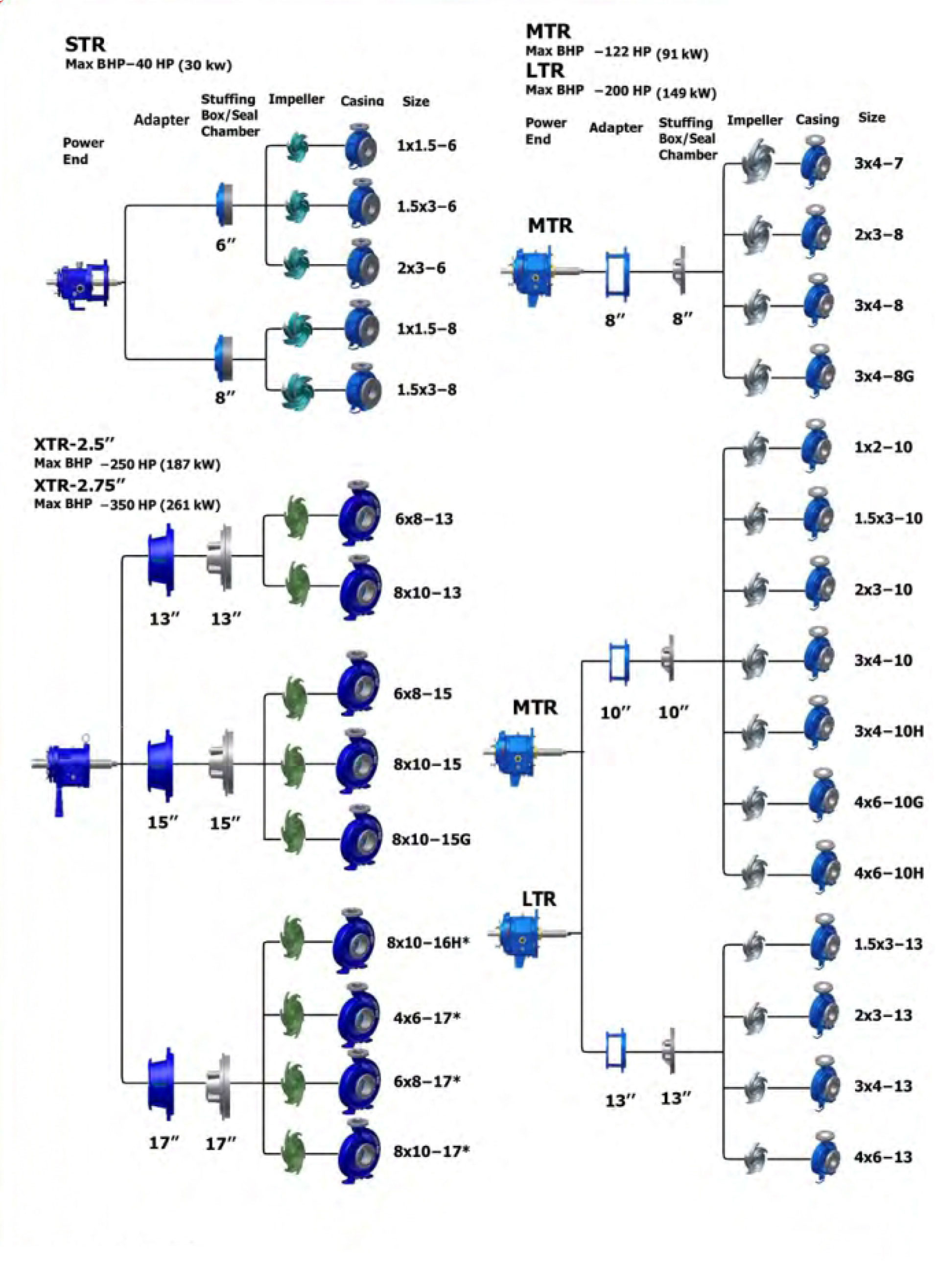

Technical Sheets

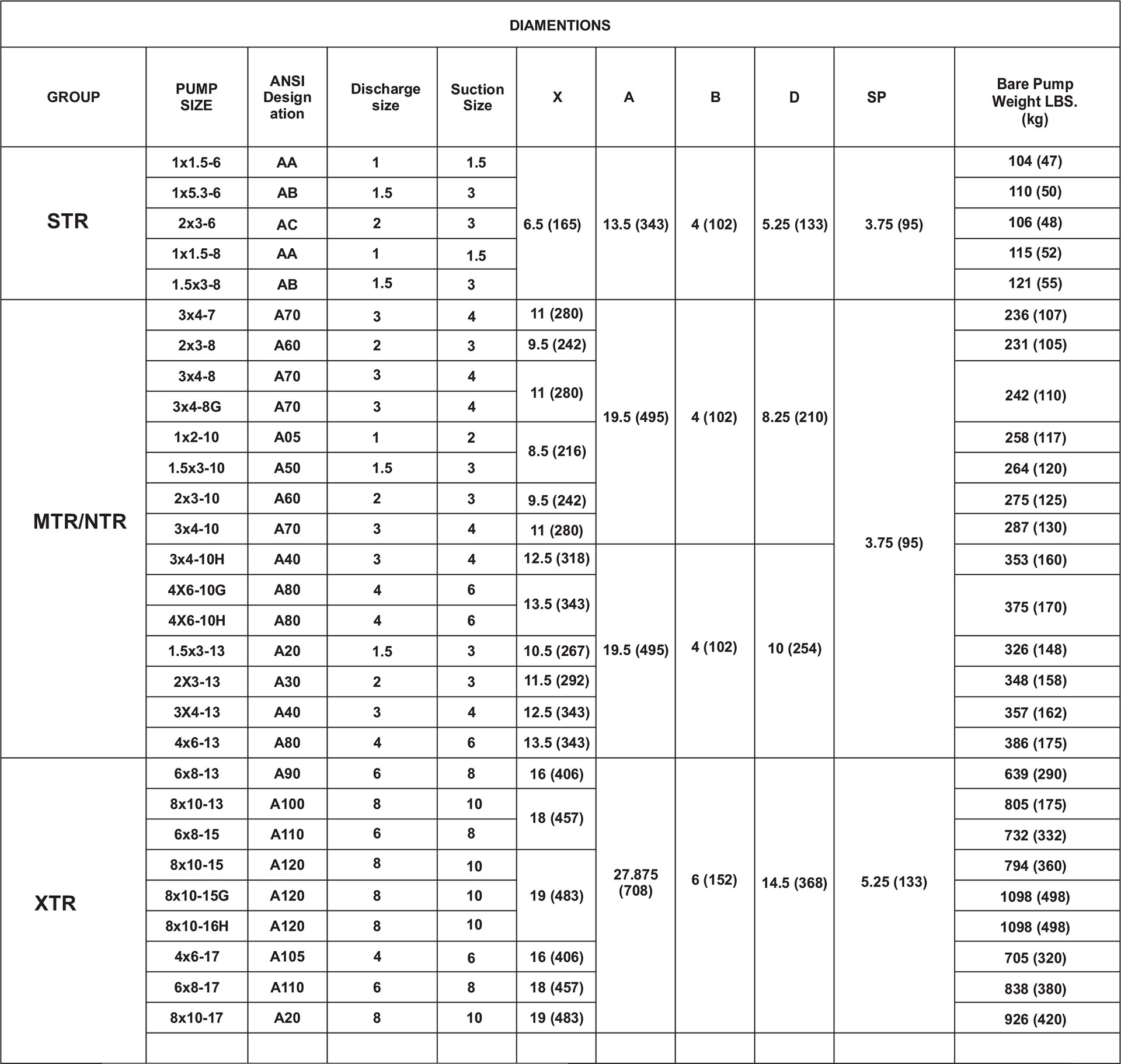

STR

MTR/LTR

XTR

• All dimensions in inches and (mm). Not to be used for construction

• All dimensions in inches and (mm). Not to be used for construction

Low Flow Pumps

- Concentric Casing

- Radial Vane Impeller.

- Very efficient at low capacities.

- Ideal for small and batch processes.

- Works very well at Throttle valve conditions.

- Maximum Capacity: Upto 50 cu.m/hr.

Non-Clog Pumps

- Concentric volute casing with recessed open impeller helps in pumping all spherical solids, slurry, sludge, grit, and stringy or fibrous material without clogging.

- Very adaptive to handle solids in liquid suspension without much degradation.

- Reduction in redial loads leads to smooth operations in throttled valve conditions.

- Most of the parts are retrofit/interchangeable with existing Investa ANSI series pumps.

Flow Solutions for Every Industry

Find Answers to Your Key Questions

Whatsapp

Whatsapp

Linkedin

Linkedin